Flexible Films Packaging

LPP provides innovative solutions to manufacturer’s packaging challenges.From basic food packaging structures to advanced packaging designs, LPP provides advanced performance, supreme quality and service to large MNC, medium sized & small sized FMCG players in Pakistan and global clients. LPP is market leader in flexible film technology combining the science of engineering & innovation to create films, packages, and pouches for food & medical industry.

LPP flexible packaging plant is designed to produce high gloss, high barrier multi-layer special

films like;

BOPP, PET/PE, PA/PE, EVOH, Anti-fog, UV light barrier films with extremely high puncture

resistance to cater the need of food industry.

With the help of these special films, customers can extend the product shelf-life and reduce

spoilage which comes out as cost saving & better profits.LPP strongly believes in Hygienic production, certified Food Grade (Halal) & Recyclable materials.

Market Segment for Films:

1- Poultry- Raw Poultry/Marinated/Cuts/Sausages

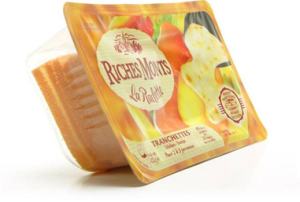

2-Dairy- Cheese, UHT Milk, Milk, Yogurt Pouches Films

3- Fresh Fruits & Vegetables

4- Dates

5- Meat- Boneless/ Bone-in / Cuts

6- Seafood-Fish / Prawns

7 -Dry Fruits- Peanuts/Almonds/Apricot/Nuts

8-Oil/Ghee Packaging Film

9-Snacks Films

10-Medical Films

11-Detergents / Soaps

12-Laminated Films

Flexible Films Key Features:

1. High Puncture Resistance

2. Excellent Thermoforming Properties

3. High Gloss with excellent transparency

4. Maximum Barrier for inert gases

5. High Sealing Integrity

6. Easy Peel

7. Transparent / Printed

8. Different Roll Sizes

Flexographic Printing Features:

1. Flexographic Printing is widely used in Europe, as it is food & medical

friendly as it is quick drying and able to use non-toxic inks.

2. With high resolution printing, package looks appealing , desirable and

premium

3. Due to motion control and perfect synchronization this avoid misprints

in long printing jobs.